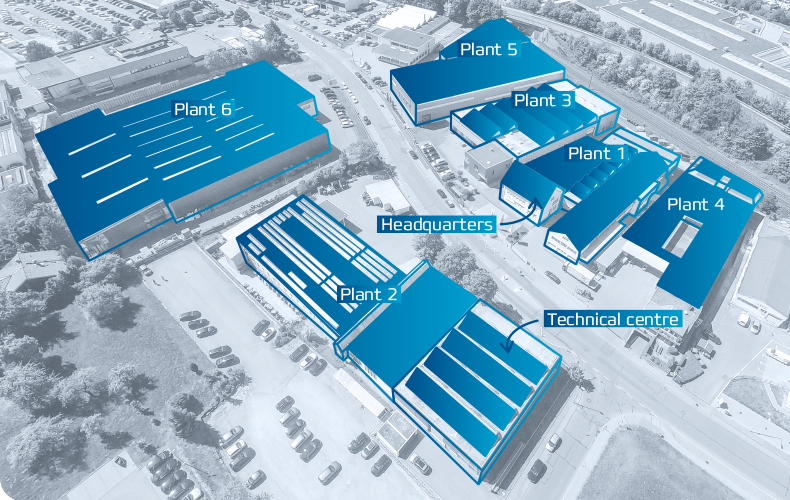

Time and again, Franke has built new production facilities in the immediate neighbourhood of its first plant. They are a visible expression of continuous growth – and a strong commitment to Aalen as a location.

Who would have thought it: 68 years later, the first administration building from 1956 (centre) is surrounded by six factory halls. The new Plant 6 tops off Franke’s ensemble perfectly.

The first property the company owned was built in 1956 on a 16-acre greenfield site in what was then Röntgenstraße (now Obere Bahnstraße) as a “two-storey factory building with administration and residential buildings”. Erich Franke himself moved into the latter. Just four years later, the hall was extended. In 1961, an extension was also added to the administration building, which from then on served as the executive office.

When Franke carriage slides began to open up new customer groups in 1975, there was no longer enough space on the site. Franke acquired a suitable site directly opposite on the other side of the road and built another production facility, Plant 2, on it in 1977. A completely new administration building was built in 1981 and already extended for the first time in 1984.

A sharp increase in incoming orders, particularly for linear guides, necessitated new machines, additional employees and the introduction of shift work. The space for this was created in 1985 by renting a hall (Plant 3). Three years later, Franke became the owner of the rented property. This was primarily due to the ongoing modernisation of production machinery and processes, which in turn led to the acquisition of Plant 4 in 2004.

Following the expansion of Plant 2 in 2012, Franke increased its production capacity by 30 per cent in 2017 with the construction of Plant 5 due to continuing high demand, particularly for large-diameter bearings for medical technology.

In the anniversary year 2024, the pioneering new Plant 6 will begin operating. The largest investment in the company’s history to date will create around 4800 square metres of production space on one level. Previously dispersed manufacturing processes will be combined into self-sufficient production units. Production-related office workstations on a 300-square-metre gallery will enable a matrix organisation system to be introduced for the specialist departments, with cross-team, process-oriented work. Once completed, the new plant will not only significantly reduce throughput times, but will also make a forward-looking contribution to Franke’s goal of climate-neutral production with its energy-efficient KfW 40 standard. Last but not least, it will also offer space for 140 diners in a modern staff restaurant. //