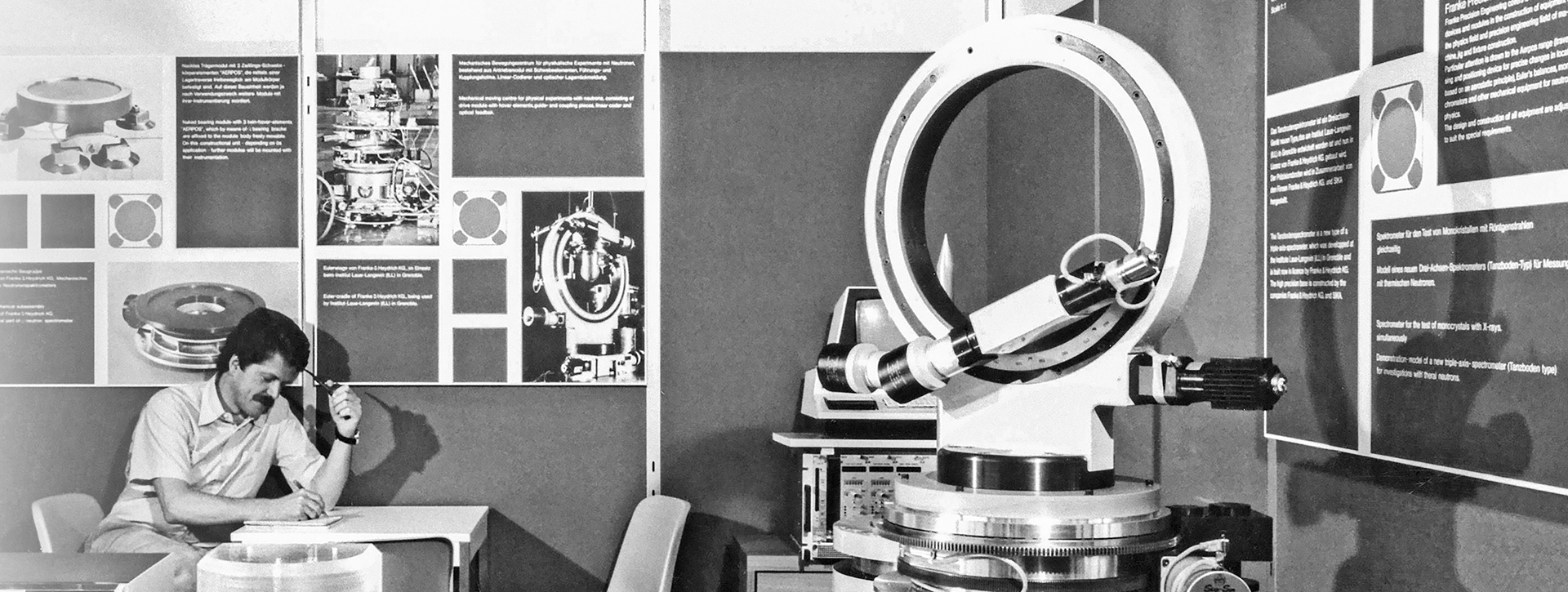

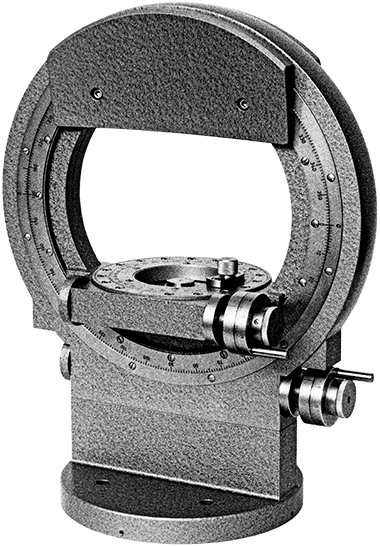

Maximum Franke precision is mandatory: Eulerian cradles are used in crystallography to position samples in three-dimensional space.

As early as 1962, connections were developed with companies involved in the manufacture of devices for X-ray and neutron diffraction measurement. The growth in this customer segment led to incredible products and even to the founding of a subsidiary: Franke Elektronik GmbH.

Eulerian cradles are high-precision instruments for sample orientation in three-dimensional space. Movable in all axes, the sample to be examined is placed in the centre of the device where it is hit by measuring beams at the ideal angle. The possibilities of using Franke wire race bearings to accommodate space-saving, highly precise bearings in lightweight aluminium housings convinced engineers at the renowned ILL Grenoble in the early 1970s to develop a complete range of positioning modules together with Franke. This gave rise to the new Precision Mechanics product division, which for a long time formed the company’s third pillar alongside wire race bearings and linear guides. A special bilingual catalogue presented the product range, which required a great deal of explanation.

Increasing automation in the field of measuring and testing also attracted the attention of other institutes and research organisations to Franke, especially as Franke positioning systems were presented to a wider audience at relevant trade fairs. For example, new customers included the Max Planck Institute in Stuttgart, the Hahn-Meitner Institute in Berlin and the Nuclear Research Centre in Jülich.

It was interesting and challenging to design and manufacture these complex devices – but the division did not make economic sense for Franke in the long term. To construct spectrometers, areas of the hall had to be cleared and fitted with special floor coverings, known as dance floors, in order to create optimum conditions for the floating elements’ air cushions to function. Research teams from the institutes spent weeks tuning the components before the system was dismantled, packaged and sent on its way. This was aggravated by the fact that the institutes’ projects were dependent on research funding and therefore could not be planned for the long term.

At the beginning of the 1980s, Franke therefore decided to abandon spectrometer construction. Only rotary and linear tables including CNC controls remained in the product range. For a time, they were distributed via the subsidiary Franke Elektronik GmbH, but this setup also proved to be unprofitable in the long term. //

Intensive marketing for a very special niche product: Precision mechanics was advertised through catalogues and trade fairs and developed into Franke’s third pillar for a while.